|

|

JSP Products

|

FlexiTEMP® 60: TC/RTD Fast-response sheath sensors with flexible stem and variety of cold junction modifications.

ModuTEMP® 70: TC/RTD Modular sensors with large selection of fittings, connections, heads and thermowells variants.

CeraTEMP® 80: TC Straight sensors available with combinations of inner and outer protection tubes from metal, ceramics or sapphire for demanding applications.

WellTEMP® 70: Thermowells with optional coating for sensor protection in harsh industrial conditions.

Sensors for special applications and complete accessories.

|

Transmitters with analogue output 4 to 20 mA • galvanic insulation • 1 or 2 channels • head-mounted, DIN rail or wall-mounted design • universal input for all common TC and RTD sensors • accuracy up to 0,1 % • LHP/HART communication for remote configuration.

Handheld LHP/HART configurators for fast and comfortable setting of transmitters in the place of installation.

Stabilized power supplies with galvanic insulation.

|

|

|

D2410, D2411, D2412: Standard pressure transmitters for common applications up to 60 MPa.

D2510, D2610: Intelligent pressure transmitters up to 4 MPa with high accuracy, compact dimensions and range setting.

DMP Series: Universal high precision pressure transmitters up to 60 MPa with long-time stability and Ex certification.

Comprehensive accessories: 1-way valves, 2/3/5-way manifolds, impulse pipes, assembly parts, calibration, …

|

CK, CB, C4B: Centric and 4-hole orifices with chamber or spot tapping, available up to DN 1000 and PN 320.

DK, DB: Nozzles with chamber or spot tapping, available up to DN 600 and PN 320.

CMT, CMT4: Complete orifice metering runs with straight sections and instrumentation with approving the TCM gauge type for invoicing measurement.

Design according to ISO 5167 in compliance with PED97/23/ES, installation between flanges or welded into conduit, optional materials and extractions, accessories.

|

|

|

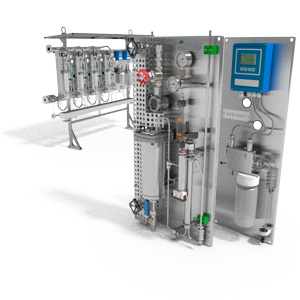

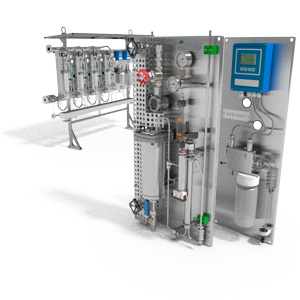

StemSET / WaterSET – Panels for sample conditioning

• Effective control of media's temperature, pressure and flow.

• Convenient for on-line measuring, sampling and further analysis.

• Versatility in use due to a modular design.

• From 1-channel panels to complex multichannel systems.

• Turnkey deliveries including project documentation, installation and commissioning.

Panels for sample analysis meet all the necessary requirements that modern analysis requires. The wide range of analysers fully covers the needs of the energy sector.

|

|

|